About CoolLaser

"It's a dream come true that uses the power of light to remove rust, paint films, and toxic substances."

The year was 20XX. In the midst of a forest of many buildings and an economy supported by roads and railroads, the endurance of the workers, who were covered in dust and working in a harsh environment to remove rust and paint film, had reached their limit. Then suddenly a young man and a girl appear. They used a device that they claimed was "Invention of a professor," and what a magic! They were able to remove rust and paint film with ease! The name of the device, which emits an intense light, is "CoolLaser”. Following in their footsteps, many others have taken up the CoolLaser, tackling high and narrow places with ease. They have taken on the challenges of the world's most difficult places.

The CoolLaser is a dream technology that uses the power of light to remove rust, paint films, and toxic substances. 2008 saw the start of development, and after repeated improvements along with higher laser output, the basic mechanism has finally reached a level that can withstand practical operations. Using the power of light to remove adhesives such as paint, rust, and toxic substances. We are still working on development toward the commercialization of laser cleaning in outdoor construction, which has never been realized in the laser industry before.

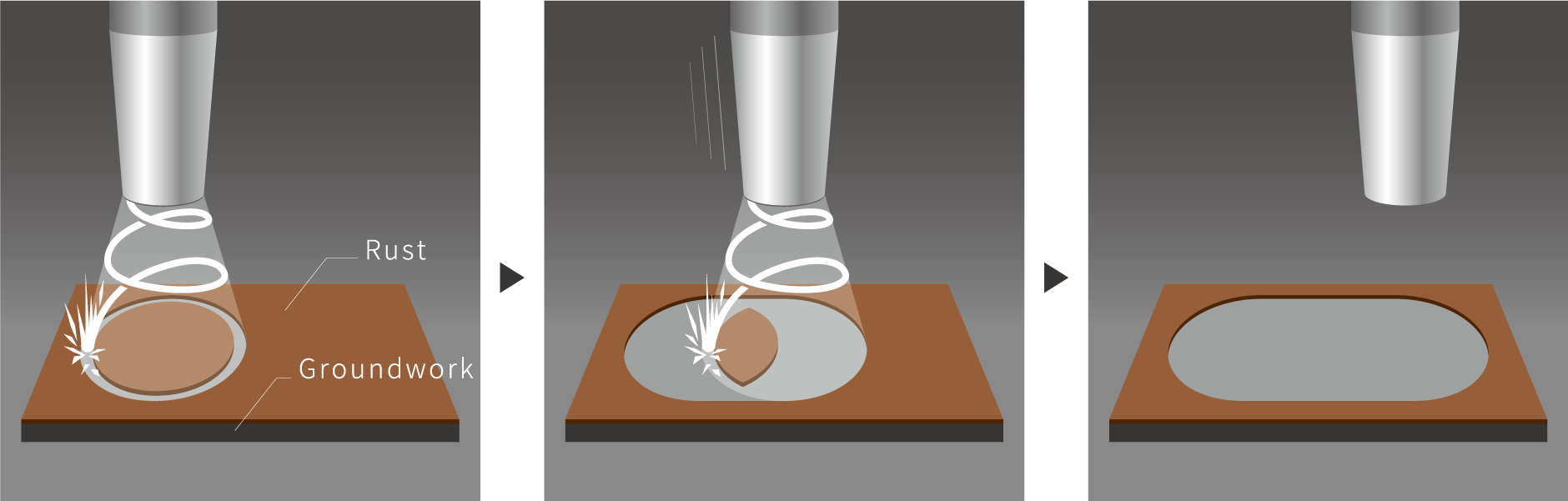

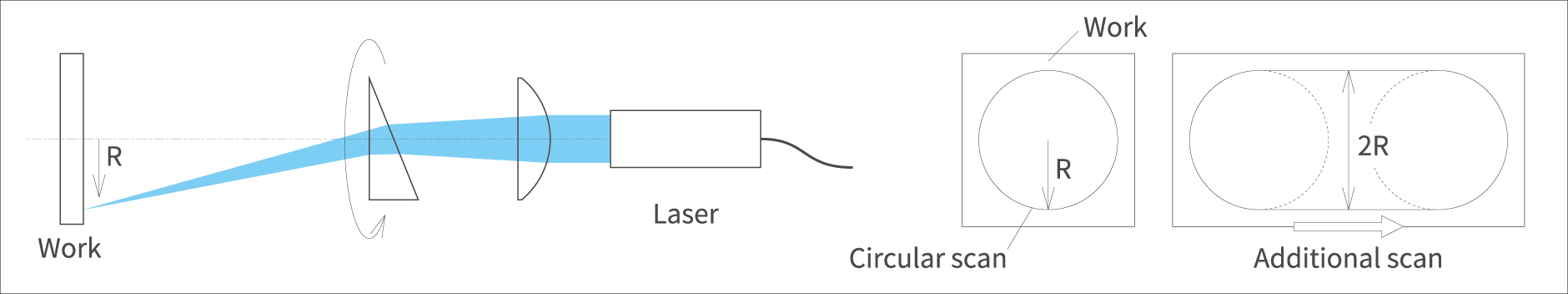

CoolLaser features high-intensity laser beam focused on a single point that moves in a circular pattern at high speed to instantaneously melt, evaporate, or thermally fracture paint films, rust, and metal on the surface. CoolLaser is a unique product that removes salts and has a low amount of industrial waste.

Patent

The technology used in CoolLaser® is patented.

Patent No. 5574354 CoolLser®.

Before & After

Case 1: Treatment on narrow sections

Case 2: Microfabrication

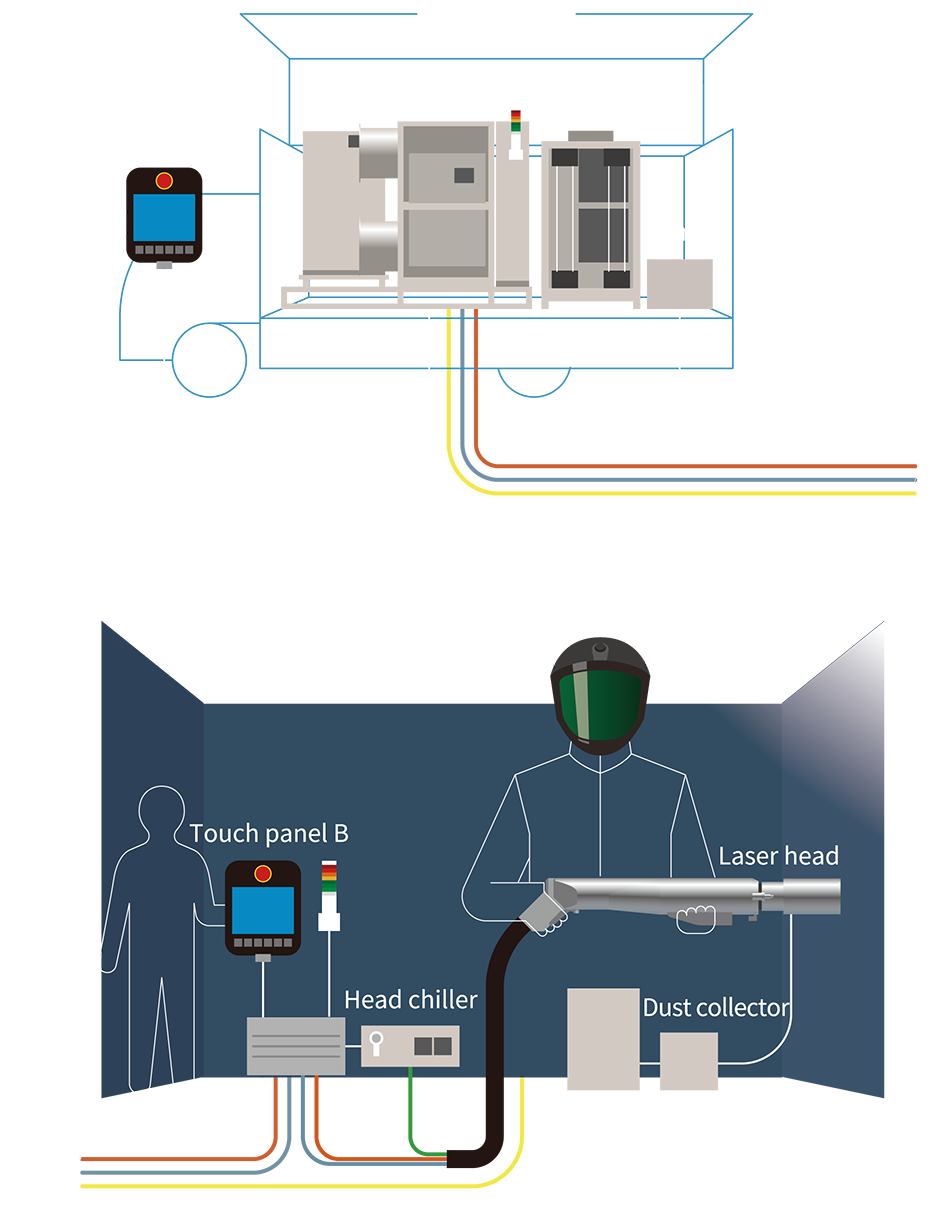

System Overview

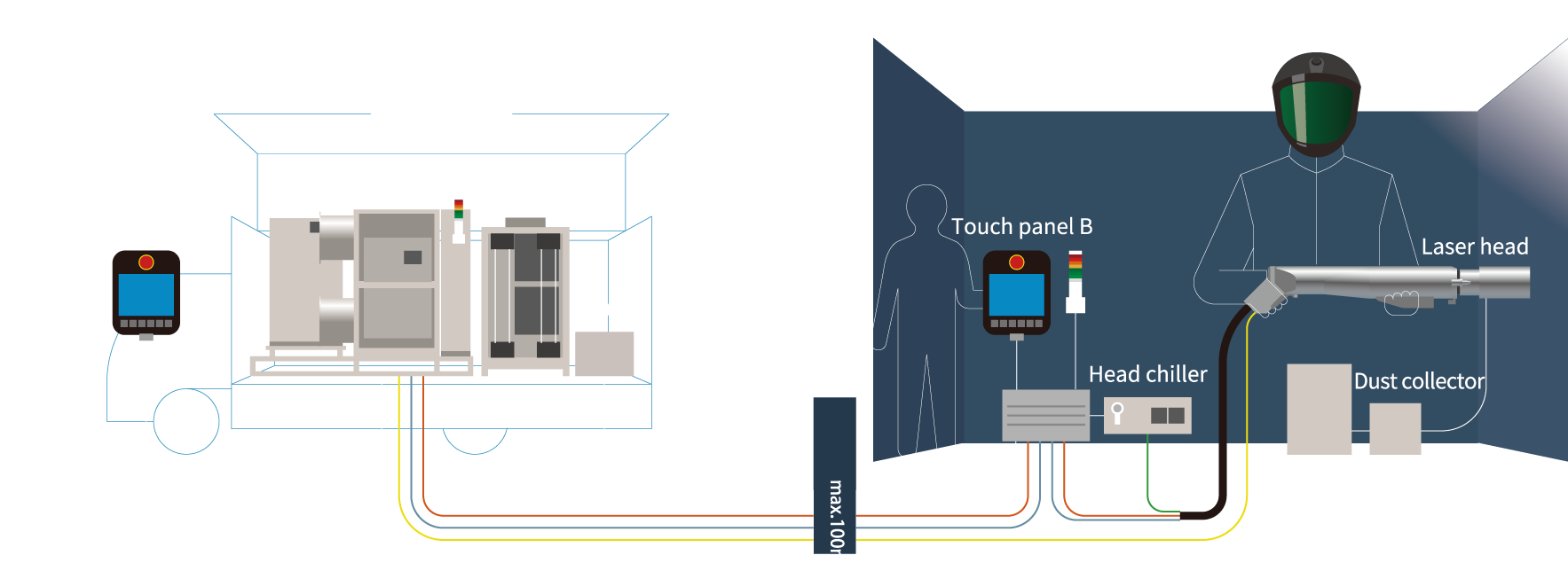

By connecting the system vehicle carrying the main equipment to the work area with a cable, the CoolLaser enables workers to in areas that are inaccessible to vehicles. In addition, the proprietary equipment and the placement of laser supervisors allow workers to concentrate on their work in a safe environment.

Research Publication

2022/3/5

R&D results were presented at Japan Society of Civil Engineers (Western Japan).

2022/3/4

R&D results were presented at the Japan Society of Civil Engineers (Mid-Japan).

2021/10/8

The interim review of the "Research and Development of Surface Preparation Methods Using Laser Surface Treatment Technology" conducted with the Public Works Research Institute has confirmed that the goals of the project have been achieved.

2019/12/27

TOYOKOH's research and development has been selected for the "Innovative R&D Promotion Project for Social Infrastructure Development" by the National Research Institute of Public Works. Click here to see the press release.

For those considering CoolLaser installation

CoolLaser is used as a rust and coating removal technology mainly for maintenance work on bridges and other infrastructure structures. Recently, it has also been used to remove white rust from hot-dip galvanizing on steel towers, and is expected to continue to play an active role in outdoor construction work in the future.

We are committed to providing the sincerest support to our customers who are considering laser installation.

If you have any maintenance problems, please feel free to contact us.

Advantages of using CoolLaser

life extension

Invisible salt that continues to cause rust can be removed.

Remaining fine rust and salt that cannot be seen cause rust to emerge again even after painstaking efforts. CoolLaser helps prevent recurrence of rust because the instantaneous high temperature of CoolLaser evaporates not only rust but also salts.

Improved workability

Work is comfortable and effective, even in tight spaces and on uneven surfaces.

Absorption of the laser light removes rust and paint film from the object, allowing the work to be completed smoothly even in intricate working environment. In addition, the light has no recoil, and the operator handles only the lightweight head part, allowing even operators with small power to use.

Clean

Environmentally friendly technology because there is no waste other than the removed material.

Since no substances such as water or sand are used, the only waste generated by the work is the original objects to be removed, such as rust and paint films. These materials are also evaporated by the laser and collected by a dust collection mechanism, making the work site clean and environmentally friendly.

Flow from inquiry to start of construction

Step 1.

Contact us

We will contact you within 3 business days of receiving your inquiry to discuss the background and details of your request.

Step 2.

field survey

Confirmation of objects to be irradiated and site survey.

Step 3.

Estimate reply

We will prepare an estimate based on the survey.

Step 4.

start of work

The installation will be performed safely in accordance with the safety guidelines of the Laser Installation Study Group.

Transportation Method

The equipments are loaded onto a wing vehicle and transported to the area close to the site. If you have any questions, please feel free to contact us using the inquiry form.

Work Environment

Irradiation work will be performed in accordance with the safety guidelines established by the Laser Construction Research Association. Please contact us for details.

System

We setup a processing system consisting of workers (including shift workers) and a site manager. Depending on the nature of the work, an increase in the number of workers may be expected.

Environment

A laser control area is defined for safety reasons. Shielding materials are used to prevent laser beam leakage outside the defined area.

protective gear

We wear respiratory protection, laser safety glasses, protective clothing, etc. for safety of workers.

For inquiries about our qualification program and safety guidelines, please contact us.

FAQ

Q. What safety measures are in place?

A. Our construction work is performed in accordance with the "Safety Guidelines" (published in July 2021) established by the Laser Construction Research Association. The organization also offers training with a certification for "laser irradiation treatment installers," who have skills in safety and handling of laser equipment during installation, and "laser irradiation treatment management technicians," who are capable of planning construction, safety management, and quality control for the proper implementation of outdoor laser construction work.

Q. Are qualifications required?

A. CoolLaser can be used by acquiring the qualifications of "Laser Irradiation Treatment Installer" and "Laser Irradiation Treatment Management Engineer," which are the qualifications of the Laser Construction Research Institute.

Q. Is it possible to perform test irradiation on samples prepared here?

A. We will discuss this matter with the customer on a case-by-case basis. Please contact us using the inquiry form.

Q. Are there any materials unsuitable for laser irradiation?

A. Highly reflective materials such as stainless steel, thin materials or flammable materials are not suitable.

Q. I would like to see the actual product.

A. Visits are available. Please make a request using the contact form and we are happy to accommodate you.

Other detailed questions can be found on the FAQ page.